Top Methods for Spent Caustic Treatment: A Complete Guide for 2025

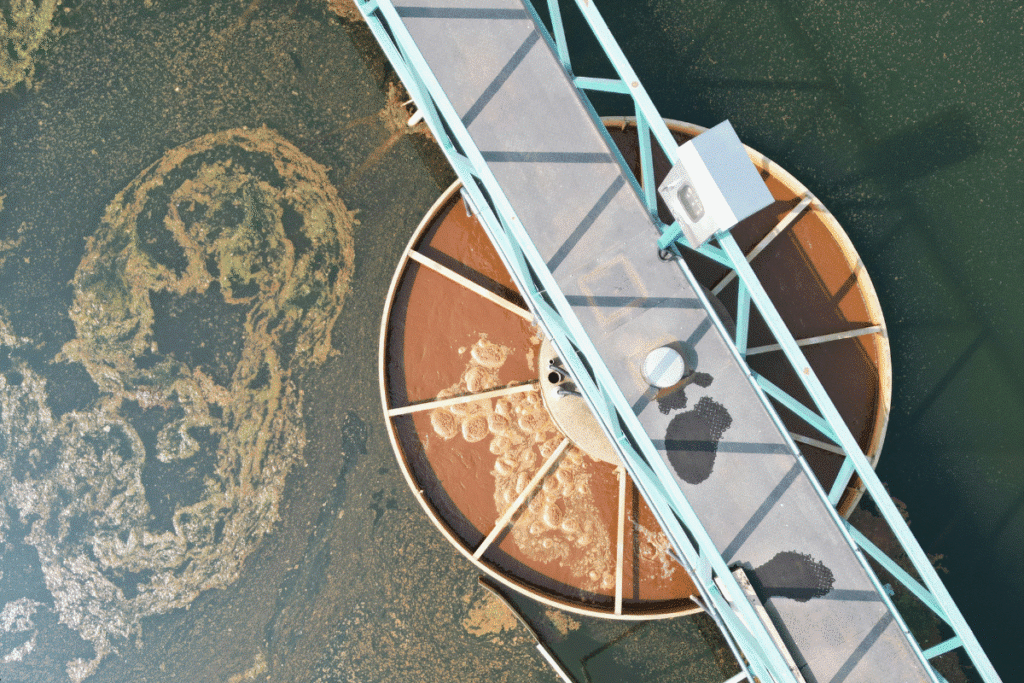

Industries worldwide continue to expand rapidly, especially in refining, petrochemicals, and gas processing. With this growth comes the challenge of managing hazardous byproducts. Among the most difficult waste streams to handle is spent caustic — a highly alkaline, foul-smelling wastewater generated during refining and chemical production.

Proper spent caustic treatment is not just a regulatory requirement — it is critical for protecting the environment, ensuring workplace safety, and supporting sustainable industrial growth. As we move into 2025, industries across the globe are adopting more efficient, compliant, and

eco-friendly methods of treatment.

This blog highlights the top technologies used in spent caustic treatment, their workingprinciples, and why they matter.

Understanding the Challenge of Spent Caustic Waste

Spent caustic streams typically originate from cleaning and scrubbing operations where sodium hydroxide (caustic soda) absorbs acidic contaminants such as hydrogen sulfide (H₂S), mercaptans, and phenols. These compounds make the waste toxic, corrosive, and odorous.

If not treated properly, spent caustic poses serious environmental and operational risks. Choosing the right treatment method is therefore essential for safety, compliance, and sustainability.

1. Wet Air Oxidation (WAO)

One of the most established methods, WAO oxidizes organic and inorganic contaminants at high temperature (150–320°C) and pressure using air or oxygen. It significantly reduces chemical oxygen demand (COD) and neutralizes the caustic nature of the waste. WAO is especially suitable for sulfidic and phenolic spent caustic streams, making it a preferred option

for refineries and chemical plants.

2. Biological Treatment Systems

Traditional biological systems struggle with highly toxic waste, but advanced bioreactors with adapted microbial cultures are proving effective. Often combined with pre-treatment steps like dilution or oxidation, biological systems provide a sustainable and cost-efficient option for certain types of spent caustic streams.

3. Thermal Oxidation (Incineration)

For highly toxic or concentrated streams, incineration provides a robust solution. The waste is burned at temperatures above 850°C, requiring advanced emission control systems. While energy-intensive, it is often used when no other method is technically feasible.

4. Chemical Oxidation

Using oxidizing agents such as hydrogen peroxide or Fenton’s reagent, this method effectively treats smaller volumes or specific contaminants. It is commonly used as a pre-treatment step,preparing the waste for further biological or physical processes.

5. Advanced Oxidation Processes (AOPs)

AOPs combine technologies like ozone, UV light, and hydrogen peroxide to produce hydroxyl radicals that degrade persistent organic compounds. Highly efficient and scalable, AOPs represent a future-ready solution for industries seeking innovation-driven treatment systems.

6. Neutralization and Precipitation

Often the first step in treatment, neutralization adjusts the pH by adding acids (such as sulfuric acid), which leads to precipitation of sulfides and heavy metals. While not a complete solution, it makes the waste safer to handle and prepares it for advanced treatment stages.

Final Thoughts

The global refining and chemical sectors face mounting pressure to manage spent caustic responsibly. With tightening regulations and sustainability at the forefront of industrial strategy, investing in advanced treatment technologies is both an environmental necessity and

a business advantage.

At WP&E Technologies, we deliver customized, efficient, and regulatory-compliant spent caustic treatment systems that help industries worldwide minimize risk, reduce costs, and operate sustainably.